What Causes Metal Injection Molding to Need Sintering?

- mimsupplierus

- Mar 26, 2025

- 4 min read

Metal parts constructed through metal injection molding (MIM) need the fundamental sintering process for their manufacturing.

People will understand that MIM sintering is crucial in making high-quality engineered steel parts for MIM.

Fundamentals of Sintering

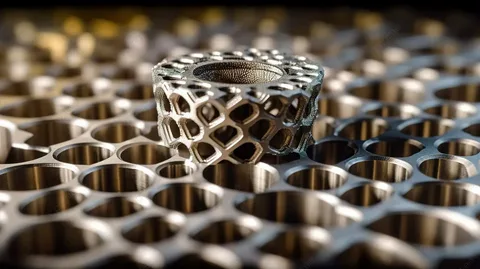

The fundamental metal injection molding process requires heating metallic particles while compacting them to create solid, dense structures with proper strength. Sintering enables the production of numerous components that serve different sectors.

Auto component creation is one of the leading applications that utilize sintering technology. Automobiles employ sintered metal bushings, bearings, and gears mainly because of their superior strength and ability to resist wear and maintain proper dimensions. The diverse attributes of each material allow their utilization in custom applications. Stainless steel powder is usually used in corrosive conditions, but manufacturers prefer copper alloys because they perform better in electrical environments.

The Benefits of Sintering

Powder Metal Sintering methods offer significant advantages in developing better mechanical qualities of the end product. A slight heat below the melting point changes the crushed metal material during this method. The powder particles unite while being heated below the melting point, enhancing material properties and component density.

Raising metal powder to high heat through sintering leads to interparticle neck formation and complete porosity elimination. Because of denser part components, the end product achieves enhanced strength and increased resilience. Through this process, metal alloying elements become more loosely distributed to improve strength and hardness and reduce material wear.

This method enables production from different materials, including stainless steel, ceramics, and titanium. The technique adjusts to other specifications, allowing detailed and complex building of materials with various properties.

Moreover, it optimizes time and cost. The process reduces production expenses and manufacturing time since it requires minimal post-processing steps such as welding or machining.

Procedures for the Sintering Process

Standard operating procedures in several phases are required to achieve successful sinter metal injection molding.

The destruction of binder from mold-produced components serves as the starting procedure of debonding. Solvent debonding with chemical intervention and thermal debonding that relies on controlled heat are the main methods for performing this process. The debonding procedures attempt to extract organic binders from parts through methods that preserve their dimensional stability.

Following debinding, the actual sintering procedure comes next. Sintering is heating a part to a high temperature in a regulated environment. The selection process for sintering temperature and duration becomes more precise according to the choice of material. The climate conditions used during sintering play a crucial role in determining the qualities of the processed item.

The sintering operation lets operators achieve controlled oxidation and reduction reactions through hydrogen or nitrogen atmospheres.

Final sintering happens when metal particles complete structural interconnection to form one unified solid piece along with densification. Product density with accompanying mechanical properties emerges from the duration of the sintering process.

The introduction of heat treatment and finishing methods after sintering refracts the part into improved surface standards and multiple other features. The process of sintering is controlled by different gas environments, including hydrogen and nitrogen, which helps manage reaction-based processes.

During sintering, metal particles partially fuse to create densification, forming a solid structure. Item density and mechanical properties develop during the specified sintering time period.

The part receives additional post-sintering treatments, including heat treatments and finishing processes, to enhance its surface characteristics and other attributes.

Considerations for Sintering Temperature

Metal injection molding depends on the chosen material to determine its perfect sintering temperature. The choice process must be thorough since it will determine the outcome. Formed metal components get their final characteristics and dimensional precision from the sintering temperature, which plays a fundamental role. Here are some essential factors to think about when calculating the temperature:

Selecting Materials:

The temperature span needed for materials to sinter differs from material to material. Students must understand the characteristics of their chosen material. The selection of proper temperature parameters demands evaluation of thermal conductivity, melting point, and degree of shrinkage.

Dimensional Precision:

The finished products' dimensional accuracy directly relates to temperature factors. Poor dimensional stability will result when operating below the proper temperature threshold because of insufficient densification. Severe distortion and shrinkage appear because the set temperature exceeds the proper levels. The appropriate balance must be found to obtain the required dimensional precision.

Issues with Sintering

Metal injection molding experiences different production challenges before securing quality fabrications of high-grade metal parts. Several problems in the processing method stem from the complex nature of procedures and the properties of utilized materials.

The Major Problems Which Occur During the Sintering Processes Include:

Distortion and Shrinkage:

At this stage, the metal powder particles join together to reduce the material volume. Due to this shrinkage, dimensional errors may result from the pieces' warping or distortion. Achieving the final shape and dimensions requires careful shrinkage control and minimal distortion.

Densification:

The entire product needs complete densification before it attains the necessary mechanical qualities. Multiple factors related to powder particle distribution shapes and the presence of impurities make achieving high density challenging during this process. The correct sintering methods allow densification to reach increased levels.

Pollution and Oxidation:

Due to the high temperatures used for their execution, metal particles may oxidize. Methods to prevent the surface production of oxides that could alter mechanical characteristics need proper implementation due to oxidation effects. Sintering quality maintenance depends on the success of minimizing both oxidation and contamination processes.

Consistent Heating:

Ensuring regular and regulated shrinkage and densification during sintering requires uniform heating. Uneven heating may result in the parts' characteristics and dimensional correctness variations. Optimizing the heating parameters and designing the furnace properly can facilitate overcoming this obstacle.

Sintering Time:

Gaining the correct properties in parts is an essential requirement. The sintering duration should be managed carefully since extended exposure leads to unwanted grain enlargement and decreased material properties—insufficient time results in insufficient bonding, which results in a poor density outcome. High-quality parts need the perfect combination of temperature and time parameters.

Hot isostatic pressing together with spark plasma and microwave and conventional sintering techniques have been developed to solve these problems during the manufacturing process. The material being processed, the intended part qualities, and economic considerations are some elements that influence the technique selection. Each technique has pros and downsides.

Conclusion

MIM sintering is essential. When different metallic powders are combined, they enable the production of durable and long-lasting parts. Sintering produces three main advantages: stronger material, improved dimensional accuracy, and enhanced surface quality.

Comments