Understanding the Benefits of Metal Injection Molding Process

- mimsupplierus

- Jul 4, 2025

- 2 min read

Processo MIM combines the best aspects of traditional plastic injection molding. It also offers design freedom and cost-effectiveness of plastic injection molding with its high strength and durability.

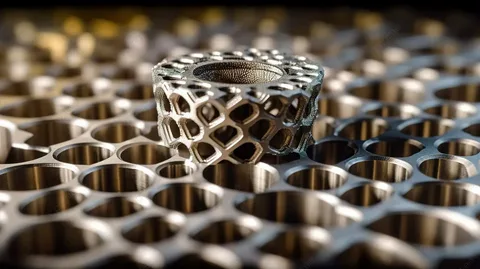

Metal injection molding is an advanced production process for fabricating solid metal parts through the principles of injection molding technology. Ideally it is designed for molding ceramic materials to accommodate metal substrate.

Understanding the Process of Metal Injection Molding

During processing metal injection molding, fine metal powders are blended with plastic binder for producing a feedstock for injection molding. The blending is melted down, formed and called using conventional molding machine. Every step of the process is critical to ensure the fabricated components meets the required geometry, chemical composition and physical attributes,

What are the Advantages of Metal Injection Molding?

Design Flexibility

The parts can be made with intricate internal structure, thin walls and complicated shapes to make it possible to produce functional and aesthetically pleasing components. Apart from designing complex geometries – MIM offers tight tolerance that is essentially crucial to ensure proper fit and function of the components.

Cost Effectiveness

More manufacturers are embracing MIM Metal Injection Molding Process for its cost-effectiveness. Metal injection molding is considered cost-effective for various reasons including the reduced labor and waste cost.

The process is highly automated that reduce the need of manual labor and it can result in significant labor saving. The process ideally generals very little scrap that can reduce the need for secondary operations like finishing and assembly that also contributes to lower cost.

Consistent Quality

Since the manufacturing process offers consistent quality, it is easy to achieve high repeatability. The process is highly automated and repeatable that ensure each part is produced exactly the same.

Since the manufacturing process takes place in a controlled environment – it can reduce the risk of contamination and defects. Also, the high pressure and heat helps to eliminate porosity present in the feedstock.

Material Selection

A wide range of options are available with metal injection molding including stainless steel. Titanium and low-alloy steel. It definitely offers the engineers the flexibility to choose the finest materials according to the specific application.

Density and Strength

MIM parts are fabricated with high degree of density that results in excellent mechanical properties including strength and hardness. It makes MIM a great choice for various components to withstand stress and wear.

MIM is less expensive than machining, investing casting and stamping especially, when you are producing in large quantities. MIM can be performed on wide range of metal including:

Stainless steel

Carbon steel

Copper alloy

Nickel alloy

Iron

Cermet

Cobalt alloy

Wrapping Up

MIM requires high capital investment and processing costs. It is not suitable for small production run also it is a complicated metal fabrication process. If you want to outsource an efficient production team, get in touch with MIM Supplier. They can support high-volume manufacturing for geometrically complex parts with intricate details.

Comments