Pre Sintering in Powder Metallurgy: Improves Quality and Efficiency of the Sintering Step

- mimsupplierus

- May 27, 2025

- 2 min read

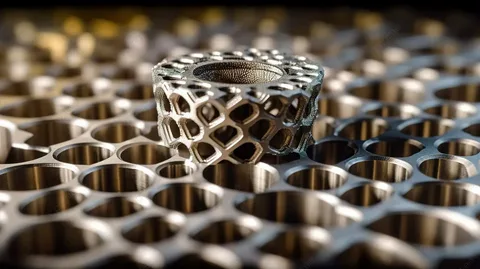

Powder metallurgy is a popular manufacturing method that has roots in the ancient period. People used metal powder to make a variety of tools and even precious jewelry. The demand for complex parts started some decades and it is still increasing. Powder metallurgy has emerged as an advanced production process for making high precision parts. Pre Sintering in Powder Metallurgy is seen as one step before the final sintering stage. It is not always required for all PM processes. Pre sintering process is needed in increasing the quality and reliability of the final product. Sintering is an affordable method to produce high performance parts. Preheating, main sintering and cooling are three important stages of Sintering. This process has helped in achieving tensile strength and mechanical strength.

Pre Sintering is a Key Step in Powder Metallurgy

Pre Sintering is considered as an important step in the powder metallurgy manufacturing process. It is used in manufacturing of some metals that needs high melting points. It is also used in the production of specialized applications like Zirconia. Powdered metal component is gradually heated to 500-900°C in this stage. Pre Sintering enables removal of lubricants and binders from the compacted powder particles. These lubricants and binders aids in compaction but it must be removed to prevent bonding and densification between powders. It also reduces oxides on the surface of the metal powders. These oxides must be reduced before the powder particles can be sintered and densified to produce high performance components. It reduces porosity, improve mechanical properties, and also enhances the final product's strength, durability, and consistency..

Sintering Definition Powder Metallurgy and Its Importance

Sintering Definition Powder Metallurgy is an important process in powder metallurgy manufacturing process. In involves consolidation of powder materials into a solid piece. In fact, it is a thermal treatment that transforms powdered materials into a dense and solid structure. This crucial process typically occurs at temperatures below the melting point of the primary material. A key advantage of sintering in powder metallurgy is the possibility to create very complex external shapes and most possibly internal ones as well. This is primarily due to the fact that both the matrix that reflects the external shape, and the possible mobile punch placed inside to make a shaped hole, are made by wire EDM with centesimal tolerances. Sintering is used in producing various components including automotive parts, aerospace components, medical implants, magnetic materials and so on.

Conclusion

Pre sintering is an important step in the powder metallurgy process. It offers a strategic balance between green compaction and final sintering. It can enhance mechanical strength, dimensional stability, and machinability of compacted powders. Pre sintering ensures final sintering process proceeds efficiently and predictably. Sintering being the final stage in powder metallurgy is a critical phase. It transforms a weak, porous green compact into a strong, functional metal part. This process helps in creation of advanced materials and shapes which are in fact difficult to achieve with conventional methods. Sintering is used in real world applications such as gears, bearings, structural brackets and many more.

Comments